It can be operated according to the icon without manual, which is easy to understand.

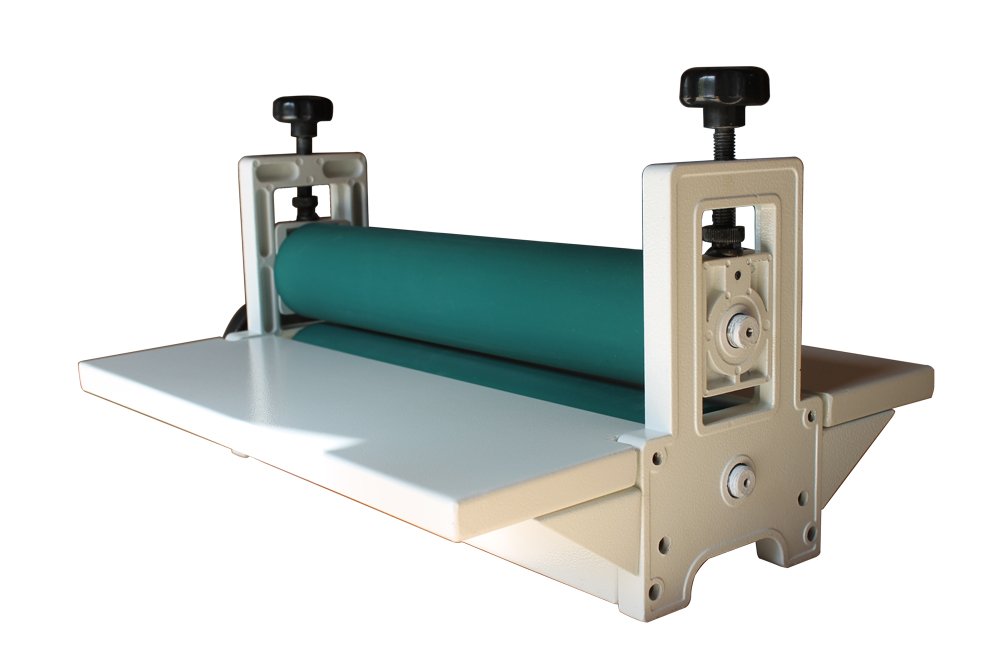

Upgraded on the previous body, with icon-style instructions printed on it. HC20 has been tested for several hours of continuous paper output before leaving the factory, maintaining a uniform paper output speed of 8 m/min, and HC20 does not need to consume wearing parts. HC20 is upgraded with three design concepts of durability, ease of use, and DIY after-sales. In order to facilitate users to use honeycomb paper to wrap items, the equipment has been upgraded with humanization on the original basis.

The packaging industry has fully entered the era of plastic ban and plastic restriction this year, choosing paper buffer packaging can solve the problem of plastic packaging very well.Ĭurrently in paper pad buffer consumables, after being stretched by the HC20 electric honeycomb paper machine, the items wrapped in honeycomb paper can protect, buffer, shockproof, and play a great role in express packaging.

0 kommentar(er)

0 kommentar(er)